Identifying

Customer Needs

intended application analysis • laboratory trial measurements • on-site trial measurements

Improving the efficiency and durability of the protection provided by coatings is our primary motivation. We attentively listen to our customers about the challenges they face in achieving their coating durability goals, and we propose QCQ assisted solutions. The versatility of innovative QCQ technology opens up new and exciting possibilities, and we look forward to riding the wave of innovation together in this exciting area of corrosion engineering.

Generic/Specialty

Application Development

software and equipment customization • education and training • quality management system integration

Tailored to meet our customer needs, our applications are created based on a single premise – if we don’t feel comfortable using them, no one else will either. Fast and simple, our solutions easily integrate into systems and slip into daily business routine. The innovative nature of QCQ technology kindles interest in exploring new frontiers, and we welcome feedback and ideas that lead to continuous improvement.

Services

inspection and testing • inspection project management • data analysis and reporting • equipment rental

We support our customers along the way of reaching coating related decisions within their design and maintenance projects. Empowered by the innovative technology equally applicable to new and in-service coating systems, we strive to raise the bar of coating durability by advancing pre-qualification and providing quantitative input for predictive coating maintenance and quality control.

Who uses QCQ?

Testing and R&D

Laboratories

quantify coating degradation during accelerated exposures

speed up the coating formulation process and fine tune the coating protective properties

Coating Producers

quantitatively express the quality of their products

reliably specify coating solutions

distinguish between coating and application practice related coating defects

Coating Inspectors and

Consultants

perform fitness-for-purpose assessment of in-service coatings

expand portfolio with a novel inspection method

offer a high added value service

Asset Owners and Integrity Managers

record the coating quality throughout the intended lifetime

obtain input data for predictive maintenance

make informed decisions on coating repair and renewal

Metallic Producers

and Product QMs

quantify the impact of production process alterations

resolve curing related issues

decrease coating related warranty claims

What is QCQ?

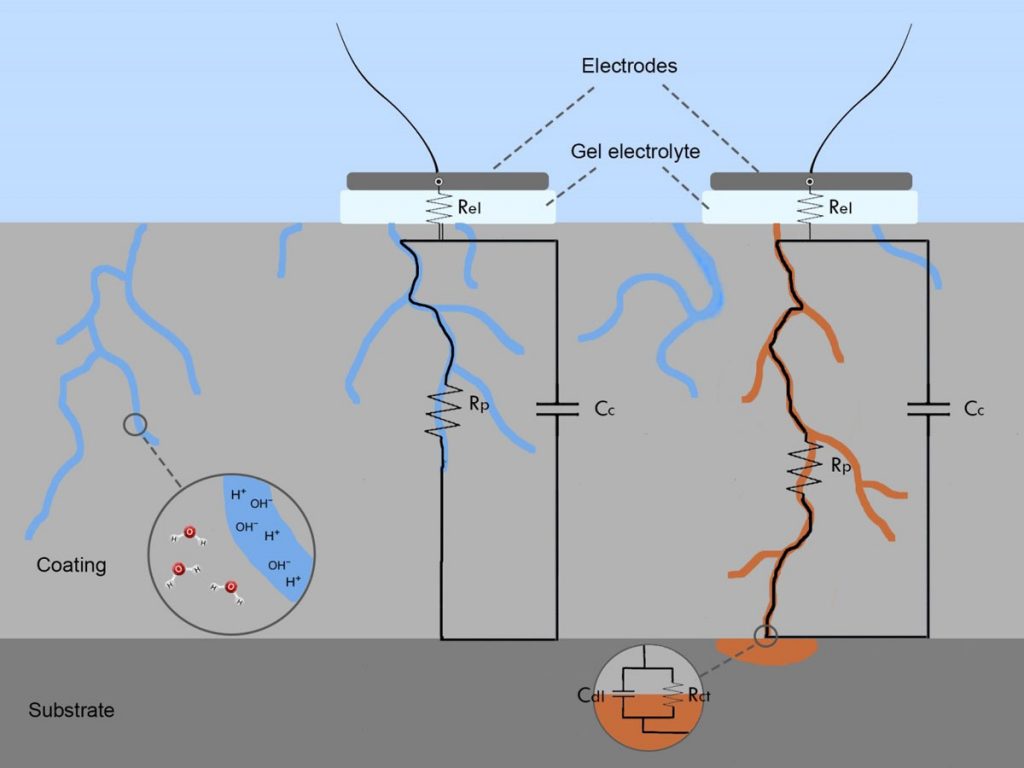

QCQ technology enables non-destructive recording of impedance Z, an indicator of the BARRIER PROPERTIES of coatings exposed to a corrosive environment.

The typical behavior of coatings involves either RETENTION or LOSS of barrier properties with exposure to corrosive environment.

The predictive power of QCQ technology lies in its high sensitivity to the loss of coating protective properties and the occurrence of corrosion BEFORE VISIBLE DAMAGE OCCURS.

The basis of the QCQ technology is the standard ISO 16773.

QCQ Output

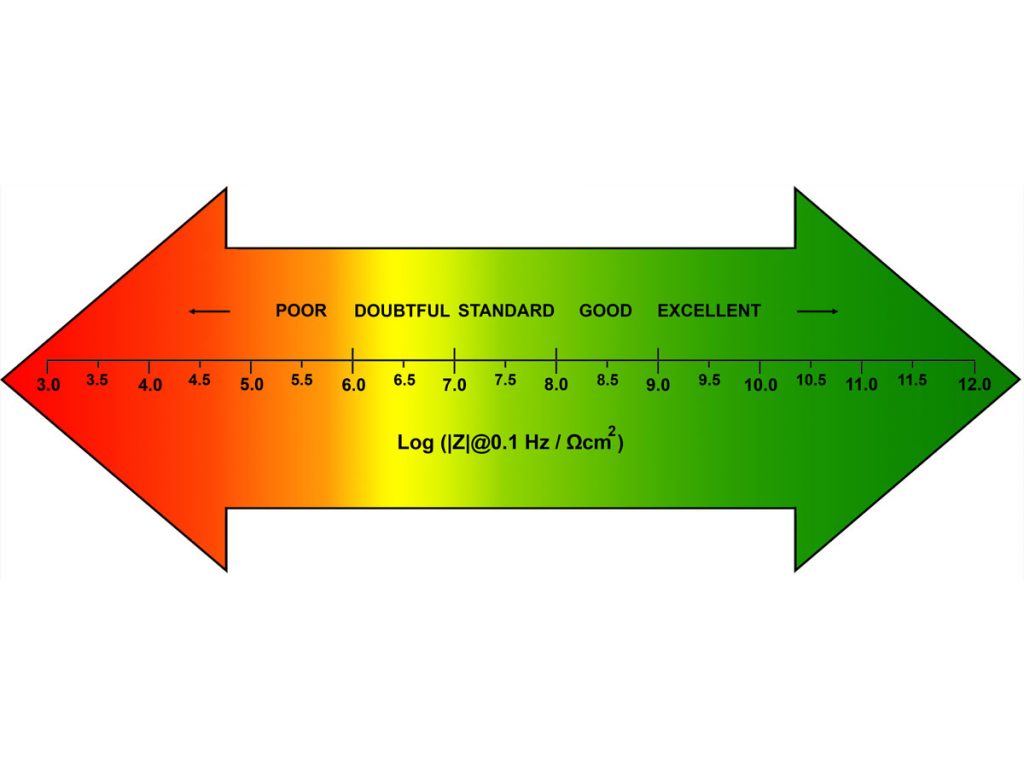

QCQ provides quantitative results on an easy-to-understand Log Z@0.1Hz COATING QUALITY SCALE.

Optional advanced corrosion potential, impedance and dielectric loss angle spectral analyses, as well as wet adhesion analysis, allow the TESTER and SPECIALIST LEVEL approaches depending on the complexity of the system being tested.